Determination of drop wire weights

| Tex cm/inch |

metr. count tex |

Denier engl. Mm |

count Td | weight NeB |

thickness g s = mm |

number per row and | |

| cm | inch | ||||||

| -9 | -111 | -80 | -66 | -1 | 0.2 | 20 | 50 |

| 9-14 | 111-71 | 80-125 | 66-42 | 1-1.5 | 0.3 | 14 | 36 |

| 14-20 | 71-50 | 125-180 | 42-30 | 1.5-2 | 0.4 | 10 | 26 |

| 20-25 | 50-40 | 180-225 | 30-24 | 2-2.5 | 0.5 | 7 | 18 |

| 25-32 | 40-31 | 225-290 | 24-18 | 2.5-3 | 0.6 | 5 | 13 |

| 32-58 | 31-17 | 290-520 | 18-10 | 3-4 | 0.65 | 4 | 10 |

| 58-96 | 17-10 | 520-860 | 10-6 | 4-6 | 0.8 | 3 | 8 |

| 96-136 | 10-7 | 860- | 6-4 | 6-10 | 1.0 | 2 | 5 |

| 136-176 | 7-6 | 4-3 | 10-14 | ||||

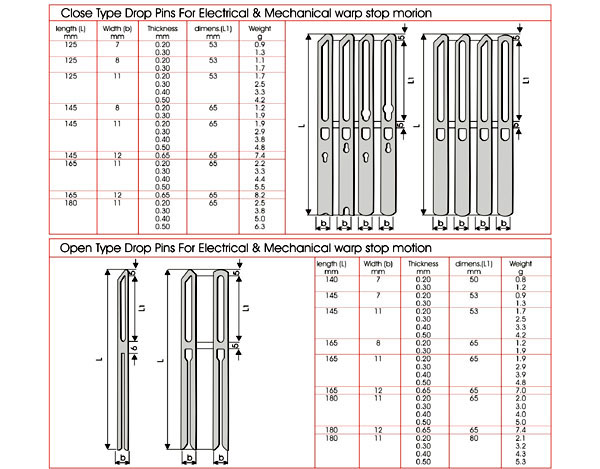

Drop Pins

Continental’s offers Drop Wires for all variety of Weaving Machines & Weaving Needs by investing our 2-generation experience, Skill, Care with right machines for required tooling.

Drop Pins manufactured from high Carbon Harden & Tempered dressed edge bright polished Spring Steel Strip on sophisticated production line matching ISO / ISI & BS standards are widely accepted.

Rust Protection:

Our Drop Pins are supplied duly bright Zinc Plated OR Nichrome Plated. 100% Rust Proof Drop Pins made of Harden & Tempered Stainless Steel Strips also can be offered for Water Jet OR Special purpose requirements.

Standard size Drop Pins Electrical / Mechanical Open / Closed type with Key Hole & Without Key Hole are indicated in Table 1 & 2 as below:

Continental’s Drop Wires control individual Warp Yarn with due care ensures stoppage of Machine in fraction of second in event of warp breakage.

Our Other products Heald Frames, All Metal REED, Electrical Contact Bars, Leno Doup Healds, Ribbon /Needle Loom Healds, Special Healds, Wire Healds, Flat Steel Healds, kindly ask for the respective catalogues or get in direct touch with us.

Odd is Even for Continental’s

Need is the mother of all inventions, we in Continental’s do not see anything impossible. We create the products for the knish market also & we can also provide the tailor-made solutions for your